Instant E-Stop Visibility — Without Rewiring or PLC Changes

The retrofit smart E-Stop indicator system

A patent-pending clip-on sensor module and indicator panel that retrofit onto any existing Emergency Stop. Instantly see which E-Stop has been pressed — wireless or USB-C operation, designed for industry, SMEs, and education

How It Works

A retrofit system designed to work with any existing Emergency Stop. No rewiring, no PLC changes.

1. Clip-On Sensor Module

Attaches directly to existing E-Stops without altering wiring.

Uses a magnetic reed or Hall-effect sensor to detect activation.

Battery powered, with optional USB-C wired power/data mode.

2. Wireless or USB-C Communication

Long-range sub-GHz wireless for most workshops and production areas.

USB-C wired mode for RF-restricted environments.

3. Indicator Panel

Displays exactly which E-Stop has been pressed in real time.

Supports optional cloud analytics for history, reporting, and multi-site visibility.

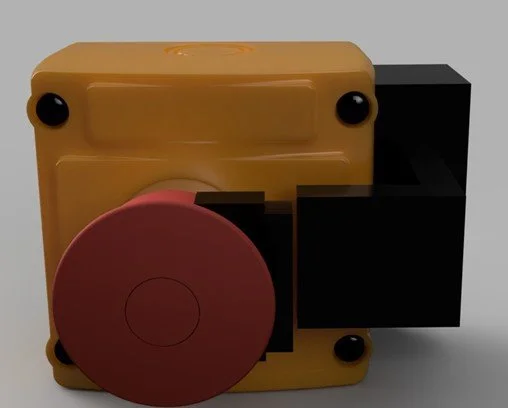

Concept Rendering — Clip-On Smart E-Stop Sensor Module

Shown attached to a standard industrial E-Stop housing. Final appearance subject to refinement.

Why It Matters

The Problem

Emergency Stops are pressed thousands of times per day across industry — but operators often have no visibility of which one was triggered.

This causes:

Unnecessary downtime

Slower response during incidents

Poor traceability and safety reporting

Increased training time

Compliance challenges for SMEs and education

Traditional “smart” systems cost £3,000–£10,000 per line and require rewiring or PLC integration.

The Solution

Close Safety Systems provides a simple, low-cost retrofit clip-on module that instantly identifies which E-Stop has been pressed — without touching the safety circuit.

No rewiring

No PLC changes

No installation downtime

Fits any existing E-Stop

Works in both wireless or RF-restricted environments

Why It’s Better

Costs a fraction of existing diagnostic systems

Fully retrofit — installs in minutes

Universal compatibility

Optional cloud analytics for history, reporting, and multi-site visibility

Designed for SMEs, training centres, education, and large industry

Product Features

🔧

Clip-On Smart Sensor Module

Attaches to any existing E-Stop without rewiring or modifying the safety circuit.

Uses magnetic reed or Hall-effect sensing for reliable activation detection.

Battery powered, with optional USB-C wired mode.

Key Features:

Zero rewiring required

Fits any industrial E-Stop

Secure clip-on mounting

Industrial-grade sensing

Replaceable battery

🔌📡

Wireless or USB-C Communication

Long-range sub-GHz wireless for workshops, training centres, and factories.

Optional USB-C wired mode for RF-restricted environments such as defence and aerospace.

Automatic fail-safe reporting ensures no signal is ever missed.

Key Features:

Up to 300m wireless range

Sub-GHz industrial frequency

Cross-wall penetration

USB-C power + data mode

Auto fail-safe reporting

📟

Real-Time Indicator Panel

Displays exactly which E-Stop has been pressed in real time.

Supports multi-stop monitoring and cloud analytics.

Fast, clear visibility for operators, instructors, and safety officers.

Key Features:

Supports multiple E-Stops

Bright 7-segment display

Audible alert option

Plug-and-play installation

Cloud logging optional

Specs at a Glance:

🔋 Battery life: 12–18 months | 📡 Range: 300m | ⚙️ Compatibility: Fits all E-Stops | 🔌 Power: USB-C / Battery

How It Compares

A Simple, retrofit-first solution that adds visibility traditional systems can’t provide

🛠️

Why Choose Close Safety Systems

Truly Retrofit-First

Industrial-Grade Wireless

Universally Compatible

Optional Cloud Analytics

Installs in minutes without rewiring or PLC changes.

Sub-GHz long-range connectivity built for factories and workshops.

Add reporting, alerting, and visibility across sites.

📡

🧩

☁️

Works with any existing E-Stop, any brand, any vintage.

Our Development Roadmap

A clear plan for delivering the full Close Safety Systems platform.

This roadmap outlines the technical, regulatory, and commercial milestones required to bring Close Safety Systems from prototype to a fully licensed and scalable product platform.

🔧 2026

Prototype Development & Pilot Preparation

✔ Q1

Finalise full functional spec

Select engineering partner

Begin radio technology testing (LoRa / sub-GHz)

CAD enclosure & PCB preliminary design

✔ Q2

Build proof-of-concept PCB

Begin firmware development

Early wireless range testing

Prepare pilot/demo materials

✔ Q3

Produce Version 1 prototypes

In-house controlled testing

Early compliance assessment

Recruit pilot sites (SMEs, education, workshops)

✔ Q4

Deploy prototypes to pilot sites

Gather real downtime/incident data

Refine hardware & firmware

Begin licensing discussions

🧩 2027

Production Engineering, Licensing & SaaS Beta

✔ Q1

Manufacture-ready Version 2 prototypes

Finalise enclosure + PCB

Expanded pilot deployments

✔ Q2

Manufacture-ready Version 2 prototypes

Finalise enclosure + PCB

Expanded pilot deployments

✔ Q3

Licensing negotiations with manufacturers

Draft royalty/licensing agreements

Closed SaaS beta launch with pilot users

✔ Q4

Licensing agreements confirmed

Deliver manufacturing package to partners

Prepare 2028 commercial rollout

🛡️ 2028

Commercial Rollout & Expansion

✔ Q1

Manufacturing & distribution by license partners

Public SaaS platform launch

Marketing campaign begins

✔ Q1

International licensing expansion

Grow SaaS dashboards & analytics

✔ Q3 - Q4

Expand partner network

Add hardware variants (range extender, low-cost variants)

Grow royalties + recurring SaaS revenue